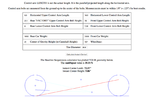

I needed to replace my rear axle upper bushing, and I found there are a couple options from Ford (OEM parts). There's the regular bushing (PN BR3Z-5A638-B) but the 2014 GT500 got a different bushing (PN DR3Z-5A638-A). I ordered both, expecting the GT500 one to be heavy-duty, visibly more stout. Not really the case- the only difference appears to be the center sleeve. On the regular bushing, it's flat steel, rolled into shape. On the GT500, it's a tubular part with serrations. Maybe it's stiffer? I have no way to know, holding them in my hands.

I'm not a big fan of poly in that location, so I'll put in the GT500 (it was only a couple bucks more), but it doesn't look like a huge improvement. In the pics, the GT500 is on the left.

I'm not a big fan of poly in that location, so I'll put in the GT500 (it was only a couple bucks more), but it doesn't look like a huge improvement. In the pics, the GT500 is on the left.