- Thread starter

- #221

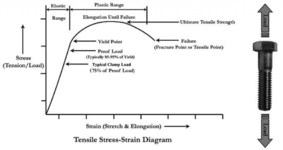

I pulled off the driver side upper bracket and there is a crack forming in the same location on it as well.

As mentioned above I have designed new plates that will use some tab and slots. It will also use carriage bolts that will snuggly fit into that square hole seen in post #212. This will allow me to mount the upper arm directly on the upper bracket and get the upper bracket closer to the frame. All of which will get me more negative camber. I just need to make sure there is space between upper arm pivot and frame. (maybe pocket the frame ) I will also weld on both sides of the joint this time to, hopefully, eliminate any future weld failures.

) I will also weld on both sides of the joint this time to, hopefully, eliminate any future weld failures.

Since I raised my roll center I was putting more force through the arms into the frame than previously. But the car seemed to handle better with the higher roll center which tells me I need to increase spring rate. I have purchased some 600# springs for the front to replace the 400#. The 600# springs will give me a higher frequency which more aligns with a race car than street car. I really was trying to do the soft spring big bar type of setup, but I just need more spring.

As mentioned above I have designed new plates that will use some tab and slots. It will also use carriage bolts that will snuggly fit into that square hole seen in post #212. This will allow me to mount the upper arm directly on the upper bracket and get the upper bracket closer to the frame. All of which will get me more negative camber. I just need to make sure there is space between upper arm pivot and frame. (maybe pocket the frame

Since I raised my roll center I was putting more force through the arms into the frame than previously. But the car seemed to handle better with the higher roll center which tells me I need to increase spring rate. I have purchased some 600# springs for the front to replace the 400#. The 600# springs will give me a higher frequency which more aligns with a race car than street car. I really was trying to do the soft spring big bar type of setup, but I just need more spring.