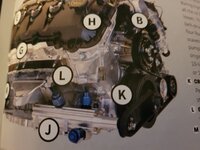

I've decided to mortgage everything of value for a custom, dream engine. The main points I'd like to discuss are the Dailey dry sump and InnoV8 individual throttle bodies that will change the overall dimensions, complicating the install. The block and heads will be original from my 2016 GT350, everything else will be custom. I'm looking for advice from anyone who has worked on these problems or knows someone who can offer expert help.

I'm hoping to lower the engine with the added bottom clearance the dry sump will provide. I'm considering both new engine mounts and the Steeda road race front K-member to achieve the lowering. Added to this problem are the American Racing headers that will need clearance considerations. It looks like the Steeda unit will help here. I guess if I can get engine mounts to lower a bit, the guys putting the car back together will have a compound problem. I don't know if the Steeda will be worth the extra costs of the part (about $1500) and the obvious added labor. There would be valuable added strength and weight loss though.

The ITBs will present not only hood clearance changes but strut tower clearance issues. The hood will definitely have new cut outs and vents for both clearance. My only regret here (other than more obvious costs) is that I really like the lines of the stock hood. I doubt the stock strut tower brace will clear the ITBs even with engine lowering. Probably no way around a custom brace -- we've all seen race cars do this -- unless someone can convince me a brace isn't needed. The Mustang GT4 has no brace but it has much more sophisticated struts and camber adjustment.

For those that haven't seen my mod details, they are Steeda lowering springs, sway bars, rear suspension links and bracing, and AP Racing brakes. Thanks for reading this far!

Brent

I'm hoping to lower the engine with the added bottom clearance the dry sump will provide. I'm considering both new engine mounts and the Steeda road race front K-member to achieve the lowering. Added to this problem are the American Racing headers that will need clearance considerations. It looks like the Steeda unit will help here. I guess if I can get engine mounts to lower a bit, the guys putting the car back together will have a compound problem. I don't know if the Steeda will be worth the extra costs of the part (about $1500) and the obvious added labor. There would be valuable added strength and weight loss though.

The ITBs will present not only hood clearance changes but strut tower clearance issues. The hood will definitely have new cut outs and vents for both clearance. My only regret here (other than more obvious costs) is that I really like the lines of the stock hood. I doubt the stock strut tower brace will clear the ITBs even with engine lowering. Probably no way around a custom brace -- we've all seen race cars do this -- unless someone can convince me a brace isn't needed. The Mustang GT4 has no brace but it has much more sophisticated struts and camber adjustment.

For those that haven't seen my mod details, they are Steeda lowering springs, sway bars, rear suspension links and bracing, and AP Racing brakes. Thanks for reading this far!

Brent