Thanks for moving the platform forward. it's amazing to read what you are going through. Fingers crossed for all to fit in place for the Nationals. The car is insane !August 2024

Update.

- Welcome to the Ford Mustang forum built for owners of the Mustang GT350, BOSS 302, GT500, and all other S550, S197, SN95, Fox Body and older Mustangs set up for open track days, road racing, and/or autocross. Join our forum, interact with others, share your build, and help us strengthen this community!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

S550 ITALIAN STANG BUILD :2018 MUSTANG PP1 10 SPEED Build Thread Profile - S550 Mustangs

- Thread starterflyhalf

- Start date

Bobidi Boobidi

This site may earn a commission from merchant affiliate links, including eBay, Amazon, and others.

More options

Who Replied?blacksheep-1

Epic Contributor

- 6,828

- 9,119

This is the best build thread ever for an S550, especially with the automatic. I was wondering if you could find another pan, then cut up the original, and welding on the new one as a deeper sump. You'd have to fab up a longer oil pickup, but all that is doable and relatively cheap.

I'm so glad you caged that car, not only will it be safer, but also more ridged.

Looking forward to more good stuff.

I'm so glad you caged that car, not only will it be safer, but also more ridged.

Looking forward to more good stuff.

- Thread starter

- #143

Grazie RobThis is the best build thread ever for an S550, especially with the automatic. I was wondering if you could find another pan, then cut up the original, and welding on the new one as a deeper sump. You'd have to fab up a longer oil pickup, but all that is doable and relatively cheap.

I'm so glad you caged that car, not only will it be safer, but also more ridged.

Looking forward to more good stuff.

The issue is I can't install a deeper one (aka the F150 PAN) because if will be too low.

Will keep an eye on possible option.

One question was should I open the filter to pick up more fluid? Every one did it. I reach the conclusion that maybe this creates even more issues (basically not enough vacuum/suction if you open too much)

Take a look of the 2 pics. Oem vs modified fully opened

blacksheep-1

Epic Contributor

- 6,828

- 9,119

Grazie Robmy pan is already aftermarket. (Trans pan not oil pan)

The issue is I can't install a deeper one (aka the F150 PAN) because if will be too low.

Will keep an eye on possible option.

One question was should I open the filter to pick up more fluid? Every one did it. I reach the conclusion that maybe this creates even more issues (basically not enough vacuum/suction if you open too much)

Take a look of the 2 pics. Oem vs modified fully opened

View attachment 97742

View attachment 97743

Seems like the open one would be better, as long as it can reach the bottom of the pan... or maybe it's made that way to keep it off the bottom of the pan.

Is there room on both sides of the pan to extend it that way instead of down?

Dave_W

Cones - not just for ice cream

Is there's enough height to add baffles & trap doors to your trans pan, like racing oil pans have? Maybe also add "kickouts" on each side to allow for more fluid in the pan?The issue is : I'm reaching forces (lateral G) and speeds I think beyond this transmission. I can touch multiple times 2 G. THE TRANSMISSION FLUID STARVED.

I'm guessing your trans cooling is a loop from/to the pan with an external pump, rather than using the trans pressure pump. Somewhat crazy idea, but if you had a port on the pressure side of the internal trans fluid, you could add something like an Accusump. No idea if the trans fluid pressure is in the same range as engine oil.

Off the top of my head, it sounds like you need less stiffness in low-speed rebound on the rear shocks - the rear shocks are "pulling up" the tires during the weight shift under braking. Problem is if the shock adjustment lets you control that, or if you need to have the shocks rebuilt with a different valving stack to change it.the rear still tends to snap on me during hard braking

- Thread starter

- #146

The trans uses internal pump only. No external.Is there's enough height to add baffles & trap doors to your trans pan, like racing oil pans have? Maybe also add "kickouts" on each side to allow for more fluid in the pan?

I'm guessing your trans cooling is a loop from/to the pan with an external pump, rather than using the trans pressure pump. Somewhat crazy idea, but if you had a port on the pressure side of the internal trans fluid, you could add something like an Accusump. No idea if the trans fluid pressure is in the same range as engine oil.

Off the top of my head, it sounds like you need less stiffness in low-speed rebound on the rear shocks - the rear shocks are "pulling up" the tires during the weight shift under braking. Problem is if the shock adjustment lets you control that, or if you need to have the shocks rebuilt with a different valving stack to change it.

For the rebound we open a nice discussion.

I thought like you did. Less rebound = tires stays down.

However. Many more expert guys suggested the opposite.

Stiffer rebound helps to reduce chassis dive because the tire has grip due to the horizontal forces due to the deceleration.in other words with steffer rebound the tires "holds down the rear part of the car

Adding rear rebound has also helped stabilize my car on braking and entry. I did not expect it to, but it was suggested by DSC . The rear still moves sometimes, but it is more gradual and controlled

Fabman

Dances with Racecars

The JRI shocks (Like Alessandro and I have) are either single (rebound and compression together or just rebound?) or they are 2 way (high speed and low speed) which is pretty confusing.

I have the doubles on front and singles on rear. There are times I'd like to add bump but not rebound or vice versa but don't really know what the shocks are actually doing.

When I ask I get: "High speed is for bumps and low speed is for platform control" but not much more.

Like Ale', I run my rear shocks very soft to help with bite off the corners which works very well.

I am not sure if I add stiffness to the rears to help corner entry if it will also add compression or if its all rebound or what. This has been very frustrating for me.

SCCA has no practice, just qualify/race so I usually don't have much time to experiment.

If anyone here knows definitively WTH is going on with these shocks I'd sure love to hear about it.

I have the doubles on front and singles on rear. There are times I'd like to add bump but not rebound or vice versa but don't really know what the shocks are actually doing.

When I ask I get: "High speed is for bumps and low speed is for platform control" but not much more.

Like Ale', I run my rear shocks very soft to help with bite off the corners which works very well.

I am not sure if I add stiffness to the rears to help corner entry if it will also add compression or if its all rebound or what. This has been very frustrating for me.

SCCA has no practice, just qualify/race so I usually don't have much time to experiment.

If anyone here knows definitively WTH is going on with these shocks I'd sure love to hear about it.

blacksheep-1

Epic Contributor

- 6,828

- 9,119

Sounds like time for a dry sump trans panThe trans uses internal pump only. No external.

For the rebound we open a nice discussion.

I thought like you did. Less rebound = tires stays down.

However. Many more expert guys suggested the opposite.

Stiffer rebound helps to reduce chassis dive because the tire has grip due to the horizontal forces due to the deceleration.in other words with steffer rebound the tires "holds down the rear part of the car

- Thread starter

- #150

Sounds like timeSounds like time for a dry sump trans pan

For a real

Sequential

Dave_W

Cones - not just for ice cream

I was looking at JRi stuff a while back, and it seemed like the doubles had different adjustments depending on what vendor you got them from, and/or what options you picked. Going off memory (bad idea), sometimes they adjusted low- and high-speed rebound, and sometimes it was HS rebound and HS compression (I could be wrong).

Ideally, starting somewhere around the $800 per shock price range, I think the shocks should come with dyno plots. Not a generic "engineering design" curve where the manufacturer puts the same graph in each box, but a real shock dyno plot with adjustment sweeps for that actual shock in the box. There will be variance shock-to-shock due to tolerances, and you can use the plots to see that 11 clicks on your left shock is the same as 13 clicks on the right one. And every time you send a shock out for rebuild, you get another dyno plot when it comes back.

For shock & suspension tuning, I found a series of articles several years ago that made sense to me. The original site is gone, but the Internet Archive saved them.

Ideally, starting somewhere around the $800 per shock price range, I think the shocks should come with dyno plots. Not a generic "engineering design" curve where the manufacturer puts the same graph in each box, but a real shock dyno plot with adjustment sweeps for that actual shock in the box. There will be variance shock-to-shock due to tolerances, and you can use the plots to see that 11 clicks on your left shock is the same as 13 clicks on the right one. And every time you send a shock out for rebuild, you get another dyno plot when it comes back.

For shock & suspension tuning, I found a series of articles several years ago that made sense to me. The original site is gone, but the Internet Archive saved them.

Dynamic Load Transfer

How weight (or load transfer) affects handling of a racing car, and terms used to describe load transfer

web.archive.org

Fabman

Dances with Racecars

Could do a separate circuit, not interrupting the current pressure circuit….just build a bigger pan with some bungs on it and plumb the sump to a separate pump and cooler and just dump it back in the pan.Sounds like time for a dry sump trans pan

Fabman

Dances with Racecars

I received no dyno plot with any of my shocks. Cortex has the shocks custom valved at JRI and there is no available info on what that is exactly. Most shocks have bump and rebound adjusters….I can understand that. I should have sprung for the Penske’s.I was looking at JRi stuff a while back, and it seemed like the doubles had different adjustments depending on what vendor you got them from, and/or what options you picked. Going off memory (bad idea), sometimes they adjusted low- and high-speed rebound, and sometimes it was HS rebound and HS compression (I could be wrong).

Ideally, starting somewhere around the $800 per shock price range, I think the shocks should come with dyno plots. Not a generic "engineering design" curve where the manufacturer puts the same graph in each box, but a real shock dyno plot with adjustment sweeps for that actual shock in the box. There will be variance shock-to-shock due to tolerances, and you can use the plots to see that 11 clicks on your left shock is the same as 13 clicks on the right one. And every time you send a shock out for rebuild, you get another dyno plot when it comes back.

For shock & suspension tuning, I found a series of articles several years ago that made sense to me. The original site is gone, but the Internet Archive saved them.Dynamic Load Transfer

How weight (or load transfer) affects handling of a racing car, and terms used to describe load transferweb.archive.org

Thanks for the links I’ll check them out.

blacksheep-1

Epic Contributor

- 6,828

- 9,119

Great minds think alike, that would solve a bunch of his cooling problems as well.Could do a separate circuit, not interrupting the current pressure circuit….just build a bigger pan with some bungs on it and plumb the sump to a separate pump and cooler and just dump it back in the pan.

blacksheep-1

Epic Contributor

- 6,828

- 9,119

It could be a low pressure system as well, as long as the sump was full, it wouldn't matter how much psi was generated by the trans itself in order to operate.Great minds think alike, that would solve a bunch of his cooling problems as well.

It would also be marketable

- Thread starter

- #156

The cooling is under control. I never overheat. The issue is all the rest. The pump I suspect is not enough during high G turn.Great minds think alike, that would solve a bunch of his cooling problems as well.

Clutches tend to slip. So we install after market ones. Now this new trans has a mod who consists in extra clutches. So we will see.

Dave_W

Cones - not just for ice cream

Does the transmission have a port that you can use for a sensor to data log the line pressure? I'm thinking that in high-g corners, the fluid is sloshing to the side, uncovering the pickup, and the pump is sucking some air. Air is compressible, so when that happens you're losing line pressure, which is what's causing the clutches to slip. Just my theory.

- Thread starter

- #158

Totally especially when you are low with the fluid. And once you go low. And the clutches start to slip you loosed clutches too.Does the transmission have a port that you can use for a sensor to data log the line pressure? I'm thinking that in high-g corners, the fluid is sloshing to the side, uncovering the pickup, and the pump is sucking some air. Air is compressible, so when that happens you're losing line pressure, which is what's causing the clutches to slip. Just my theory.

I believe I should overfill the trans a little maybe

:::cough:::sequential:::cough:::

Mad Hatter

Gotta go Faster

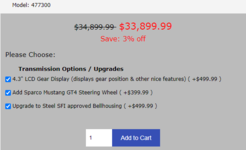

The 3% discount is a real incentive......

MMR / Hollinger 6 Spd Paddle Shift Sequential Transmission Kit [477300] - $33,899.99 : Modular Motorsports, Home of the worlds fastest Fords

Modular Motorsports MMR / Hollinger 6 Spd Paddle Shift Sequential Transmission Kit [477300] - Are you ready to take your Coyote / Voodoo Powered Ford to the next level? Then this Paddle shifted gearbox is for you! The ultimate upgrade for HPDE, Autocross and Road Racing. Same as that used in the...

www.modularmotorsportsracing.com